By Danny Chan

The negative public image of dentistry is often traced to the rotary handpiece. No thanks to its high-pitched whine and grinding sounds, the dental instrument is widely known by its infamous epithet – the dreaded drill. Dentists, by association, have too been unfairly viewed as inflictors, rather than relievers, of oral discomforts. It is therefore little wonder why the air-abrasion technique, simply by offering drill-free procedures, has helped to alleviate many a patient’s fear of dental visits.Scientifically known as Accelerated Particle Ablation (APA), air abrasion works by sending a powerful stream of air-driven particles of aluminium oxide onto the tooth surface to cut a conservative tooth preparation.

This technique utilizes compressed air and abrasive powder to wear decay off the tooth without noise, smell or vibration. In most cases, involving shallower cavities, air abrasion even eliminates the need for anesthetic injections.Despite obvious benefits, one of the reasons many dentists have avoided air-abrasion is because it generates excessive amounts of dust particles in the patient’s mouth. Just imagine the difficulty of containing all the dry particles created by an overspray of aluminous oxide particles – akin to switching on a mini sandblaster – inside the oral cavity. Air abrasion procedures also generate dust in the operatory that requires cleaning after every treatment.With the new hydro abrasion technology, dentists can now exercise better control over the powdery dispersion.

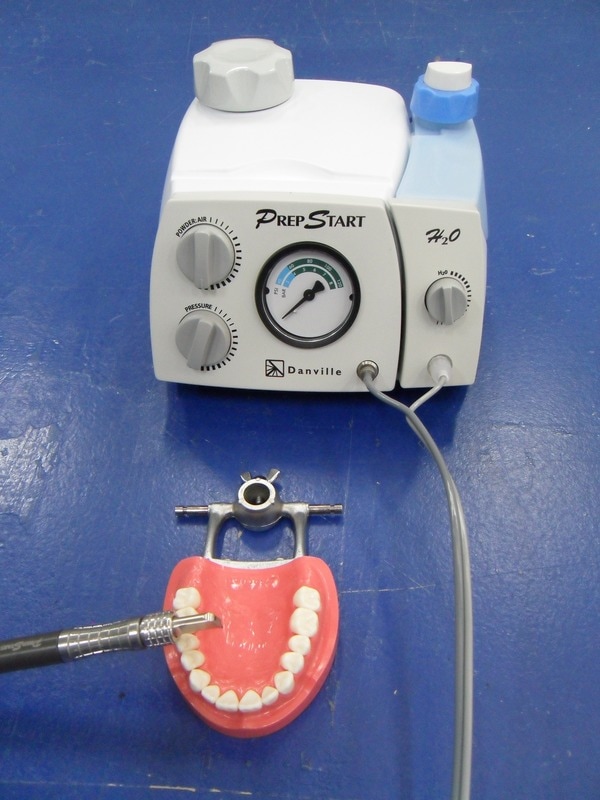

PrepStart H20 is the latest hydro abrasion unit by Danville Materials, designed to contain the dispersion of dust particles during treatment.By adding a cone of warmed water around the stream of abrasives, the contraption is able to capture almost all the dust while increasing patient comfort through the use of warm water. Meanwhile, dentists using air abrasion can look forward to the same drill-free benefits and optimal cutting results. Like its water-less counterpart, hydro abrasion offers patients virtually painless and quiet procedures that are free of vibrations, heat from friction or trauma to soft mouth tissue.Under-utilized innovation

PrepStart H20 affords the same precise abrasive cleaning that allows treatment of decay in its earlier stage. Hydro abrasion cuts tooth surfaces with absolute precision, thus removing less tooth than the drill and eliminates enamel micro fracturing common with conventional drills. Teeth treated with hydro abrasion are also less susceptible to wear and will last longer. The technique has been proven effective in repairing cracks and discolorations, preparing tooth surfaces for bonding, and performing additional procedures.

According to well-known academic dental speaker Dr Gordon Christensen (Dental Economics 2010), air abrasion and hydro abrasion units work by “propel (-ling) extremely small particles of aluminum oxide (usually 27 to 50 microns in diameter) onto tooth surfaces, cutting and making a non-traumatic, relatively painless and conservative tooth preparation.”

Recognizing the benefits, Dr Christensen added: “I do not understand why more dentists do not use (air and hydro abrasion)”.

In his review of the PrepStart H20 hydro abrasion unit, Dr Christensen noted the following:

- The addition of water lavage reduced the dust produced

- The units were designed primarily to make conservative preparations –“which they do very well”

- They cut tooth structure atraumatically

- Air abrasion and hydro abrasion cuts tooth structure easily without cracking tooth enamel

- The product offers minimally invasive dentistry

International dental lecturer Dr Mark Malterud further evaluated the Danville innovation (Fifth Quarter Seminars Newsletter, June 2010):

“The new Danville Hydro Abrasion unit is a small table top unit that delivers a consistent flow of not only aluminum oxide particles, but a consistent and focused water stream. This unit is the best I have seen”.

With Hydro abrasion, the particles are accelerated along with a spray of water. This particle/water combination prevents particles from bouncing all over the patient, dentist, and surgery. The moisture blown onto the teeth also keeps the dentinal tubules moist thus reducing sensitivity.

Dr Malterud concluded: “Hydro abrasion provides greater patient comfort and a cleaner working environment”.

Getting started with Hydro Abrasion

In Australia, PrepStart H20 is distributed by Amalgadent Dental Supplies. Specializing in innovative aesthetic and niche dental products, the company imports and distributes hundreds of clinically proven dental products across Australia and New Zealand.

Australian dentists with existing PrepStart air abrasion systems can opt for an upgrade with the H20 caddy accessory. Available as a complete new system or as an add-on accessory, the H2O is attractively styled to integrate with any Prepstart unit. For convenience and ease of cleaning, water is added to a removable tank as a self-contained feature. No electric or water connections are used.

H2O accessory includes system attached to a new Prepstart top cover that is interchangeable with any Prepstart unit. A H2O handpiece with .019” nozzle is included in the package, along with all necessary tubings and connections. PrepStart owners get to enjoy the benefits of hydro abrasion through an easy conversion process that takes the technician approximately 15 minutes to install.

Says Myer Rozen, CEO of Amalgadent Dental Supplies: “PrepStart H2O products offer maximum patient comfort by reducing or eliminating the need for injections, which is an excellent practice building feature.

“It is the gentler, atraumatic alternative to the standard drill.”

This article first appeared in Australasian Dentist

RSS Feed

RSS Feed