By Danny Chan

The dearth and high costs of maintaining skilled technicians in Australia has seen more local labs lean towards two outcomes: Outsourcing and higher technological investments. Others like A&B Dental Laboratory, however, are realising that a combination of the two alternatives makes for a better option.

In 2008, A&B founders Angelo Liakos and Bradley Donald were able to expand their services and output volume by partnering a Hong Kong-based laboratory. With a sizeable team of 120 in-house dental technicians, the foreign contractor was more than capable of keeping pace with A&B Dental’s expansion needs. The partners quickly realised that whatever initial perception they held of oversea work being sub-standard, largely fuelled by industry heresay, were unfounded.

Instead, what they witnessed from their Asian counterpart was a highly trained workforce, backed by a robust tracking system, that delivered a consistent stream of quality products. In a previous interview with Australasian Dentist, Bradley affirmed: “The lab that we use is of international standards, whether in terms of their processes, technology, training or materials.”

Angelo added: “Their consistent standard is what gets us. They are consistently improving and meeting our individual demands. We can tell them “this is what we need” and specify the requirements and it gets done. It’s difficult to do it here.

“They also have an amazing tracking system that is sometimes humbling to watch – considering the number of cases they handle on behalf of their international clientele.”

Three years on, and thanks to the fruits of globalisation – a.k.a speedy air courier services – the two seemingly disparate dental entities have forged an enviable relationship based on mutual trust and respect. Along the way, the lab owners discovered that they also shared similar ideologies for their respective businesses – holding in high regard Fordism virtues of “getting the job done in the most efficient and productive means possible”.

Technicians Shortage A Global Phenomenon

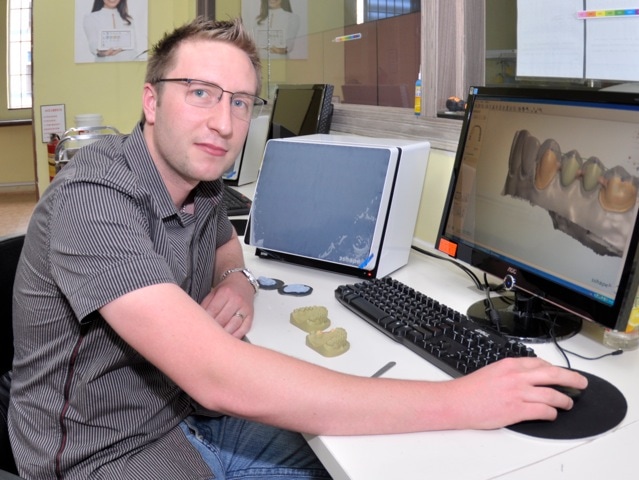

Indeed, the partnership’s recent acquisition of 3Shape and Sirona Cerec CAM/CAM systems speak volumes of their commitment towards raising the productivity and quality of their work. Investing HK$2.7 million (AUD $340,000), the labs bought a Rapid Prototyping system; two units of 3Shape scanners; the open source Wieland zirconia milling machine; and Sirona Cerec MC XL CAD/CAM systems.

According to Angelo, one of the main reasons for the purchase is to reduce dependency on skilled labour.

“The shortage in skilled workforce has been a perennial source of headache for the Australian dental lab community. Although the we feel it more acutely here, the problem is not isolated to Australian labs. Even our partners in Hong Kong are feeling it.

“Therefore in the long run, we need to increase and maintain our quality standards and efficiency without relying too heavily on manpower. High quality technicians are quite rare and are becoming expensive, even in China.”

The widespread shortage in technicians has also spawned an unhealthy employee -poaching situation between competing labs in China, increasing management woes in dealing with staff retention and costly re-training exercises.

Bradley confides: “The last thing we want is a situation whereby the quality of the product is being compromised by manpower issues.

“In view of our future competitiveness, we are confident that an open source CAD/CAM system can address our technological needs while easing the labour-intensive nature of this business. Moreover, it also gives us a technological edge over our competitors.

“Of course, our clients are ultimately the ones who will benefit the most.”

Shape of CAD Systems to Come

With 3D scanners and CAD software installed in more than 50 countries, Denmark’s 3Shape has grown in global prominence not least for its efforts in promoting innovative 3D technologies as a means of reinventing industrial processes.

On choosing 3Shape over other dental CAD systems, Angelo attributes its future-proofing technology as a primary motivation.

“The 3shape scanner system is open source, meaning we can implement new hardware and expand productivity and volume very easily. Among other things, the system allows future upgrades in abutment trimming, metal frame trimming, orthodontic, chrome design.”

In addition to the obvious benefits of purchasing Sirona’s premier line of Cerec milling units, Bradley enthuses:

“Cerec units give access to the only system that mills every chairside material from Vita, Ivoclar Vivadent and 3M ESPE. We are especially excited about the advent of VITABLOCS RealLife that will make its official debut at the upcoming IDS Cologne.

“VITABLOCS RealLife is the first and only all-ceramic block that simulates the optical characteristics of natural teeth with regards to translucency, chroma and lightness. With our latest acquisition of the Cerec machine, we are well positioned to take advantage of this exciting new development that promises anterior restorations of unsurpassed aesthetic quality.”

Since its launch in 2005, 3Shape’s dental CAD system has been one of the fastest growing products in the sector. Incorporating the freedom of digital design with future-proof lab systems, the Copenhagen-based company delivers turnkey solutions that covers the entire pre-milling process from order creation to scanning; CAD modeling to order sending; and order receiving to manufacturing preparation.

3Shape’s computer-aided approach to providing a seamless workflow falls in line with the partners’ vision. Bradley explains:

“We are changing to a computerized production line. Over the next few years, we hope to establish a fully automated lab that not only takes advantage of the precision of computer-aided software but also reduce our dependency on expensive manpower. Since the technology we are offering is cutting edge, it means our clients are among the first in the region, or even the world, to benefit from it.”

Among the cutting edge tools is a comprehensive automated system that provides an overview of and control over the lab’s administrative and clinical functions. According to the manufacturer, the software system was designed for “easy overview and effective handling of dentists, orders, clinical situation and restorative work”. Nevertheless, A&B Dental, known for its personalized service, is careful not to exploit software technology at the expense of the customer experience.

Angelo clarifies: “At A&B Dental, we believe in being personable and approachable to all our clients. We need to understand that a computer software can only go as far as speeding up the back-end work. End of day, we need to speak to a living, breathing customer-relations person.

“Having said that, we live in the digital age. It is also imperative that we provide a full digital platform for our computer-savvy customers. It also improves effectiveness in communication and minimizes mistakes that can be costly. For example, we can visually illustrate things like ‘undercuts’ and ‘margins’ with the help of digital charts and images.”

Another area in which software technology is able to replicate the human input with greater efficiency is design. All the technicians in both the Hong Kong and Melbourne labs have been duly trained in using the advanced computer-aided tools designed for anatomical crown and bridge modeling. Bradley explains:

“The 3D modeling software are exceedingly precise and free of human error, thus producing consistent results that will no doubt bear on the final quality of the restorations.

“Training is essential because the computerized procedure differs greatly from a traditional approach. Extensive practice is therefore part and parcel of the learning process.”

One distinct advantage of working in the digital realm lies in integrated devices like the 3D scanner. The scanner uses a 3-axis motion system to provide full object coverage, producing highly accurate digital impressions. The software application and 3D scanner collaborate seamlessly to generate full anatomical designs at faster rates and higher accuracy. The resulting restorations record better strengths and aesthetics.

“Based on initial customer feedback,” Bradley attests, “the fitting and margins are more accurate.”

Angelo adds: “As with any new technology, you can’t expect perfect results right out of the box. That is why we have been paying close attention to the initial feedback so that we are able to fine-tune the system until we get the best results.

“The baseline of acceptable quality in Australia dentistry is quite high compared with other developed countries. For example, microscopes trimming margin is required in Australia unlike in Holland where it isn’t obligatory.

With high-end technology, Angelo believes A&B Dental is better equipped to meet those standards at a level of craftsmanship worthy of being called Australian.

“To a customer, we are a solutions provider. It helps that we not only provide great products but also adequate support – available just a phone-call away.”

RSS Feed

RSS Feed